Machining for Nuclear / Power Generation

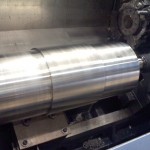

AHB tests the leading-edge of deep hole drilling, trepanning, honing, and machining services for the Nuclear / Power Generation Industries. We add value by taking material away, lots of material. If you need a hole, we can drill it. If you have a hole, we can make it bigger or deeper, straighter or rougher, smoother and more uniform. Our service levels range from rough bored holes, to holes bored and honed, to precision boring and turning of critical components machined complete and ready to assemble. We will provide your parts with less cost, less wait, and less trouble – making you more satisfied. More than a job shop, more than a machine shop, AHB is your manufacturing solution.

AHB tests the leading-edge of deep hole drilling, trepanning, honing, and machining services for the Nuclear / Power Generation Industries. We add value by taking material away, lots of material. If you need a hole, we can drill it. If you have a hole, we can make it bigger or deeper, straighter or rougher, smoother and more uniform. Our service levels range from rough bored holes, to holes bored and honed, to precision boring and turning of critical components machined complete and ready to assemble. We will provide your parts with less cost, less wait, and less trouble – making you more satisfied. More than a job shop, more than a machine shop, AHB is your manufacturing solution.

Nuclear and Power Generation Specific Services:

- Rotors for power generation

- Exotic and High Temperature materials machined

- Deep hole drilling and honing for reactor components

Nuclear Industry and Power Generation Capabilities:

- Deep Hole Drilling To 20″ ID (508 mm)

- Trepanning Up To 16″ ID (400 mm)

- Honing 1″ To 24″ ID (25mm To 609.6 mm)

- Machining (Rough, Semi Finish Or Finish) Up To 33′ (10.06 m) Between Centers

- CNC Machining Up To 160″ (4064 mm) Between Centers

- Saw Cutting Up To 16″ x 16″ (406.4 mm x 406.4 mm)

- Crane Capacity 10 ton maximum for a single piece

- Materials machined are practically all grades of metal including carbon, alloy, stainless, aluminum, titanium, and high-temperature materials

- Value-Added Services in house include 250 ton precision straightening, large shrink assembly, thread inspection and fitting, material storage, and more upon request

- Value-Added Services by qualified vendors include material supply, heat treat, blasting, grinding, plating, testing, boxing, and more upon request